Low-temperature drying and grinding mill

《 Dries and fine grinding water-containing raw material 》※ Raw materials with a water content value of 15% or more

Dries and grinds any material instantly while retaining ingredient characteristics!

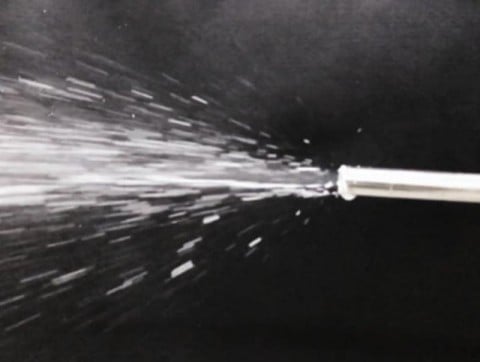

Moisture evaporates instantly in less than 1.0 seconds from drying to crushing to recovery

Drying at low temperature (100℃ or less) makes it a powder with a higher level of taste, flavor, and color.

Drying at low temperature (100℃ or less) makes it a powder with a higher level of taste, flavor, and color.

Low-temperature drying and grinding mill - Centrifugal Dryer add Mill -

Easy dries and grinding from food drying to waste disposal!

◆ Dries and grinding within 1.0 seconds (the time the raw material is inside machine)

◆ In most cases,raw materials are dried at low temperatures no higher than 100℃.

◆ Effective powdering is possible by minimizes alteration and deterioration of raw material components due to heat.

This technology is a simple, compact, highly efficient and easy-to-maintain dries and grinding device that

simultaneously crushes and dries.

It is an environment-friendly technology that enables the reuse of resources by separating and collecting resources and waste.

Raw materials and various input machines that can be input

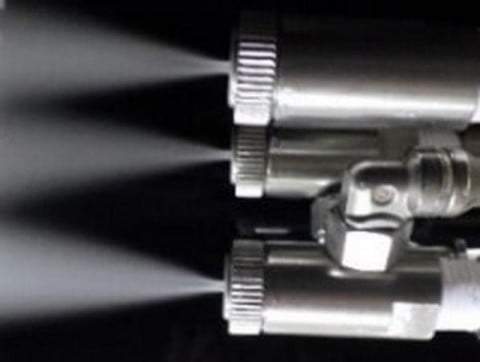

We have a lineup of input machines suitable for the condition of raw materials! (solid, liquid, slurry)

Main raw materials available

Food department

Okara (compressed)

Vegetable scraps and other food residues(Non-standard product vegetables and fruits)

Used tea leaves and coffee grounds

Fisheries residue, livestock residue, etc.

Vegetable scraps and other food residues(Non-standard product vegetables and fruits)

Used tea leaves and coffee grounds

Fisheries residue, livestock residue, etc.

Industrial department

Oil-soluble raw material

lignite

Calcium hydroxide

Sawdust (Bark chips), etc.

lignite

Calcium hydroxide

Sawdust (Bark chips), etc.

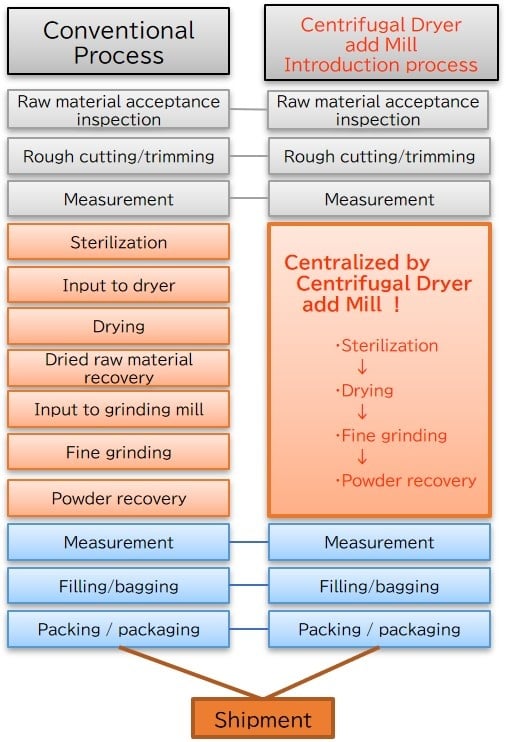

Reduction of work process

Centralized from drying to fine crushing! It is also possible to reduce the process.

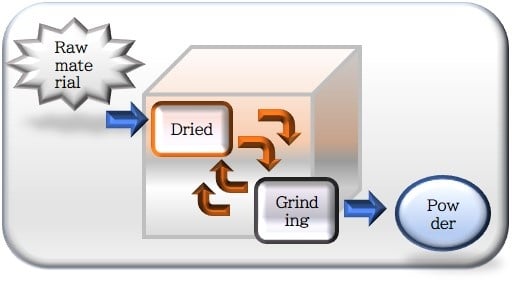

Drying-Grinding cycle

Dried ⇔ grinding time is 1.0 seconds or less!

1. Raw material particles collide with each other in a high-speed swirling airflow

2. Increasing of the raw material surface area from fine grinding enabled instantaneous drying.

3. Since dried particles are easier to fine grinding, they are fine grinding into even finer particles.

2. Increasing of the raw material surface area from fine grinding enabled instantaneous drying.

3. Since dried particles are easier to fine grinding, they are fine grinding into even finer particles.

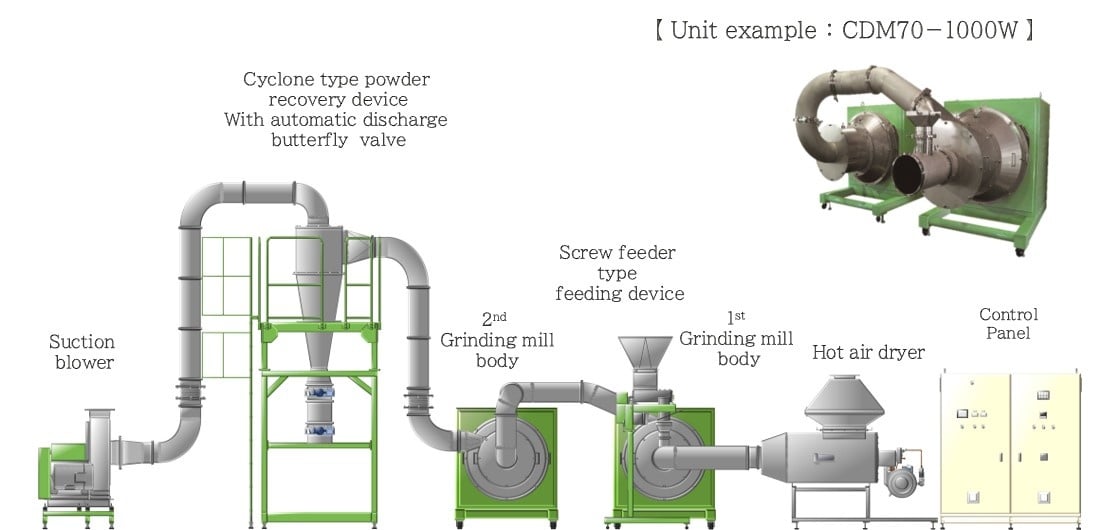

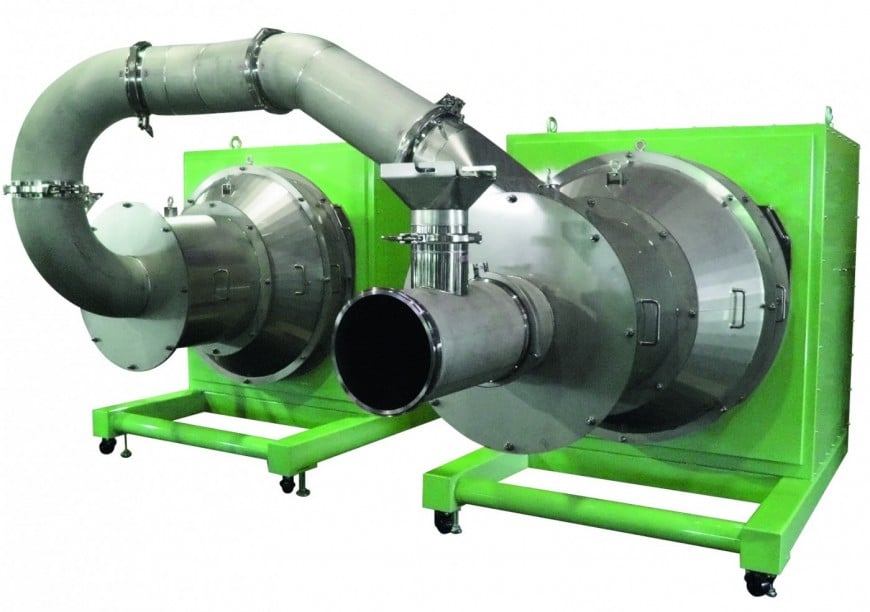

Low temperature drying and grinding mill system configuration

◆ Processing amount may vary significantly depending on the raw material and target particle size.

Thrinding e stated grinding capacity should only be viewed as a guide.

◆ Continuous butterfly valve discharge is available as an option.

◆ The equipment will be delivered on-board, and transportation costs, machine installation, electrical work, air and gas piping work will be charged separately.

◆ Since the Centrifugal Dryer add Mill does not have a filter, it is recommended to install an aftertreatment device such as a dust recovery device if necessary.

◆ Continuous butterfly valve discharge is available as an option.

◆ The equipment will be delivered on-board, and transportation costs, machine installation, electrical work, air and gas piping work will be charged separately.

◆ Since the Centrifugal Dryer add Mill does not have a filter, it is recommended to install an aftertreatment device such as a dust recovery device if necessary.

Recommended.